Kverneland 2501 S VARIOMAT

Aratro | Aratro Reversibile

Dal trasporto all'aratura in tempi record

Aratro reversibile portato ISOBUS. Nuova generazione di aratri.

Punti di forza

- FURROWcontrol con qualsiasi schermo ISOBUS

- Trasporto sicuro con TTS: soluzione opzionale per il trasporto a rimorchio

- Buri aero-profile per le migliori prestazioni di scorrimento del terreno

- Regolazione centrale rapida degli avanvomeri

- Tutte le impostazioni dalla cabina del trattore

Descrizione

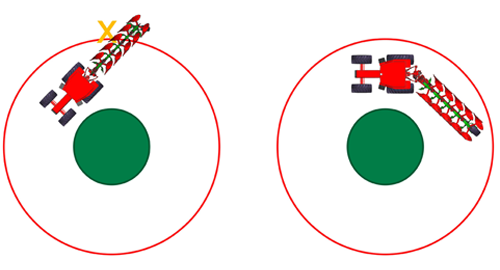

Kverneland 2501 S i-Plough è il modello reversibile portato ISOBUS ideale per l'agricoltura moderna. Consigliato per trattori fino a 280 CV (206kW), il sistema auto-reset consente di arare in qualsiasi condizione di terreno. 10 innovazioni migliorano il lavoro in campo. Definizione delle impostazioni dell'aratro dalla cabina del trattore: collegamento sicuro e senza problemi; concetto di trasporto semi-portato, l'aratro ti segue come un rimorchio (TTS); tracciatura delle linee guida semplice per i campi "non quadrati" e per le entrate e le uscite; le funzionalità essenziali sono gesite tramite ISOBUS. La funzionalità FURROWcontrol di Kverneland mantiene semplicemente e rapidamente dritte le linee di aratura. Una volta che l'ideale traccia A-B è definita, il FURROWcontrol allinea automaticamente tutti i passaggi seguenti grazie alla guida GPS (DGPS/RTK) e la

variazione della larghezza di lavoro Variomat (da 30 a 50 cm per corpo); anche la linea di trazione è regolata automaticamente.

Punti di forza

- FURROWcontrol con qualsiasi schermata ISOBUS

- Trasporto sicuro: Soluzione per il trasporto "a rimorchi"o Kverneland (opzionale: TTS)

- Buri aero-profile: questo nuovo design elimina gli intasamenti

- Regolazione centralizzata rapida degli avanvomeri per un'aratura perfetta

- Sistema di memoria unico che mantiene le impostazioni di larghezza dei corpi desiderate dopo il ciclo di inversione

- Regolazione idraulica dei corpi anteriori

- Riconsolidamento efficiente in una sola passata: compatibile con Packomat e packers

Caratteristiche

Caratteristiche

Il vostro i-Plough sempre connesso

Con Kverneland Sync, il vostro i-Plough è costantemente connesso ai servizi online di Kverneland. Progettato per la comodità e l'efficienza dell'utilizzatore, Kverneland Sync assicura un trasferimento di dati continuo tra il vostro i-Plough e le piattaforme IsoMatch FarmCentre e Kverneland ServiceCentre, consentendo una gestione ottimale della macchina e il monitoraggio delle prestazioni.

Diagnostica remota - Riduzione al minimo dei tempi di inattività

Utilizzando Kverneland Sync, la diagnostica remota è facile da gestire, consentendo ai tecnici di analizzare e risolvere rapidamente i problemi elettronici del vostro i-Plough a distanza tramite il Kverneland ServiceCentre. Questo riduce significativamente i tempi di fermo macchina in caso di guasti, assicurando che il vostro i-Plough torni rapidamente sul campo.

Gestione delle attività - Miglioramento della reportistica e dell'efficienza

Kverneland Sync permette a tutte le informazioni chiave del vostro i-Plough di essere facilmente accessibili in IsoMatch FarmCentre, la piattaforma integrata di gestione di Kverneland. Questa funzione offre un monitoraggio in tempo reale, un'analisi dettagliata delle prestazioni e un'archiviazione sicura dei dati.

Geofencing e sicurezza avanzata

i-Plough beneficia di funzioni di sicurezza avanzate, tra cui il geofencing tramite Kverneland Sync. Anche quando l'aratro non è collegato a un trattore, la batteria a lunga durata garantisce la possibilità di localizzarlo, proteggendo le vostre preziose attrezzature dai furti.

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

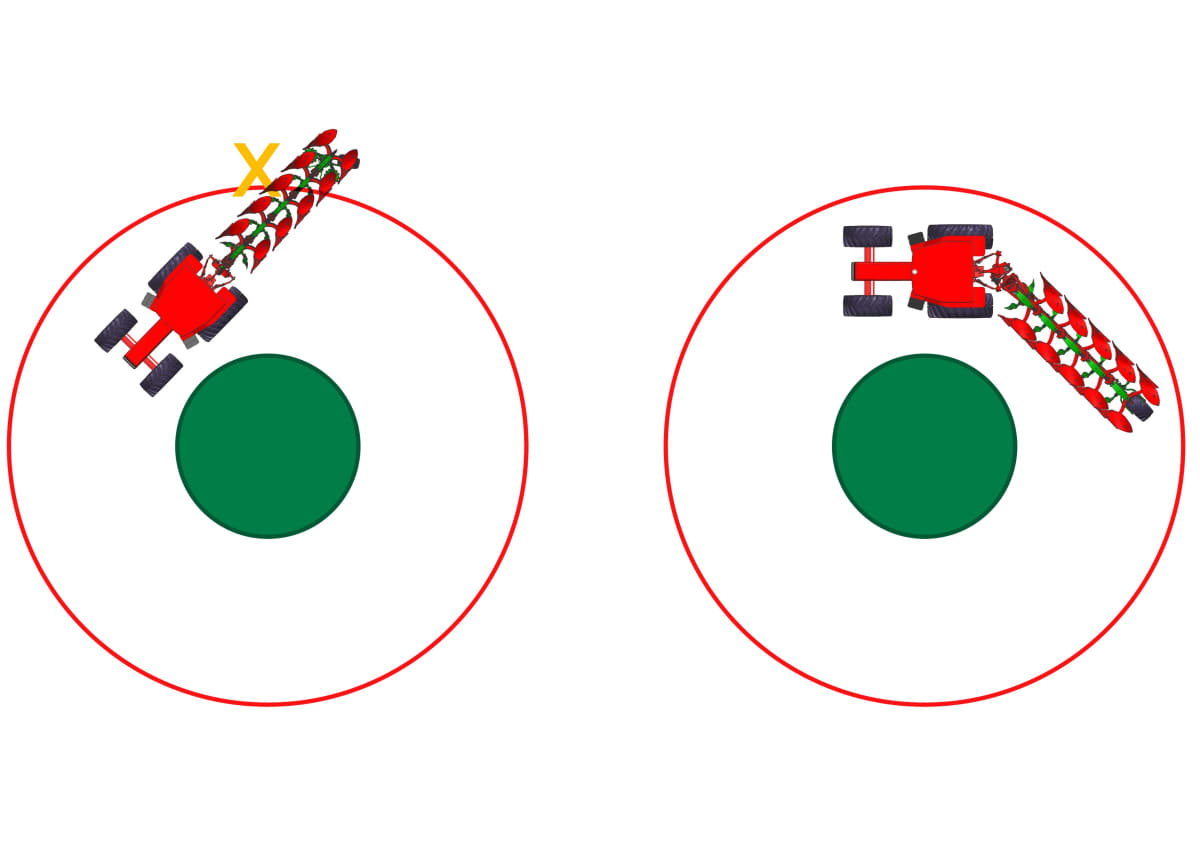

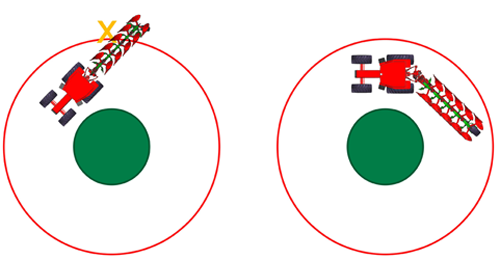

Kverneland “TTS” (Trailer Transport Solution)

- The plough behaves like a trailer. Turnable cross shaft max. 45° mutual offset during transport.

- Safe: maximum security for anything/anyone around and for the driver. No tilting out when driving in curves.

- Easy conversion from transport to ploughing.

- The Kverneland TTS is an option

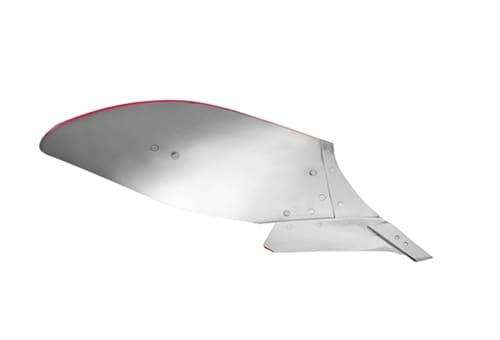

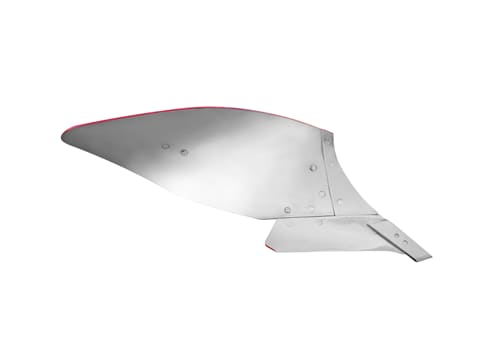

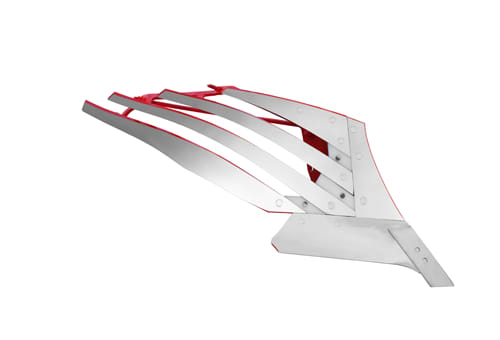

Aero-profile legs

- Special design for best soil flow.

- 80 cm leg height to prevent potential blockage in heavy residues, manure, cover crops or when ploughing deeper.

- Robust legs: pre-shaped components limiting weldings.

- Low pulling requirement and hence fuel consumption thanks to low weight hollow legs.

Auto-reset system

- Unrivalled Kverneland mechanical leaf spring system for Non-stop ploughing.

- No Maintenance.

- Legs, plough and tractor lives are protected and lengthened.

- Quality ploughing: legs release independently one from another and come back to the correct position.

- Easy adjustment of releasing forces: unscrew 2 bolts to add or remove springs.

Leaf springs |

Release Pressure kN |

Standard pack: 6 leaf springs |

11,2 |

HD pack: 7 leaf springs |

12,7 |

XHD pack: 8 leaf springs |

14,4 |

Double pack: 6+4 leaf spring |

16,9 |

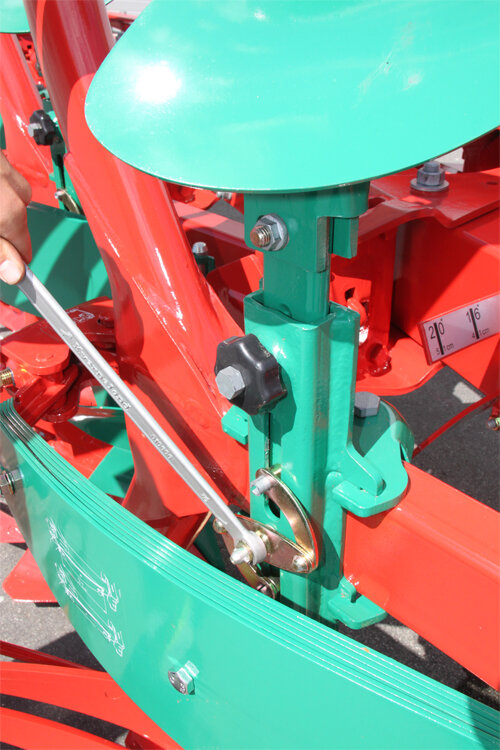

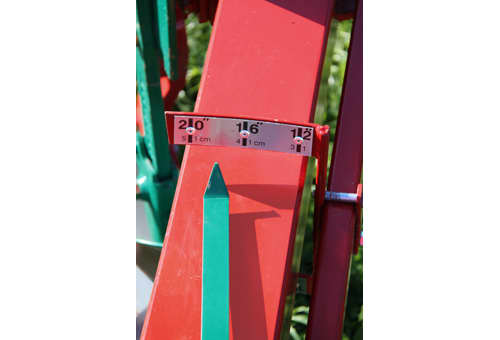

Smart skimmers adjustment

- Unique: central adjustment of skimmers working depth.

- Quick operations: right and left skimmers adjust simultaneously.

- High ploughing performance: the correct adjustment of skimmers contribute to a quality ploughing.

- Disc coulters also available: plain or notched (18”/45cm or 20”/50cm)

Importance of heat treatment

- The frame is an essential part of the plough construction. For Kverneland quality standards, a non heat treated part is a weak part!

- Kverneland frames are heat treated by induction twice. The temperature transfer to the steel is closely monitored. The frame gains 3 times as much strength. This unique Kverneland induction processes provides robustness and flexibility while ensuring an outstanding durability.

Stronger but not heavier

- For the equivalent Kverneland robustness, competitors would use more steel in thickness or in dimensions, therefore producing a heavier frame.

- Heavier frame impacts negatively pulling forces, wearing of parts, lifting capacities, tractor life time, and fuel consumption.

Long lasting

- Weldings are also a critical weakness for a plough frame. Kverneland frames are supplied as one sole part!

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

La tecnologia dell’acciaio Kverneland, trattato termicamente:

- Più di 140 anni di esperienza

- Acciai di prima qualità che resistono anche alle condizioni più difficili

- Il miglior rapporto robustezza/peso sul mercato

- Per ottenere una simile robustezza, i concorrenti aggiungono più acciaio e quindi maggior peso, fattore che favorisce un’usura più rapida, consumi più elevati e un’aratura insoddisfacente.

Acciaio Kverneland:

- Vantaggi della leggerezza: semplicità di traino/consumo di carburante inferiore/minor richiesta per il sollevamento/stress e usura ridotti/risparmio economico…

- Vantaggi della resistenza: riduzione delle rotture/meno manutenzione/riduzione della frequenza d’inversione delle parti d’usura come le punte/risparmio di tempo/mantenimento del valore di seconda mano/vita dell’aratro prolungata/risparmio economico…

Con un aratro Kverneland potete essere sicuri di lavorare efficientemente e in tutta tranquillità!

Maggiori informazioni: Kverneland Technology

Kverneland “TTS” (Trailer Transport Solution)

- L’aratro si comporta come un semi-rimorchio. L’angolazione massima della testata durante il trasporto è di 45°.

- Massima sicurezza in curva senza scodamento.

- Semplice passaggio da trasporto a lavoro tramite un pulsante in cabina.

- Il sistema Kverneland TTS è a richiesta

Buri Aero-profile

- Il design è pensato per il miglior flusso di terreno e residui.

- La lunghezza della bure è di 80 cm per evitare bloccaggi dovuti a residui o cover crop da interrare.

- Robuste: sagomate in forgiatura per limitare le saldature

- Profilo cavo che limita peso, richiesta di potenza e consumo di carburante

Auto-reset

- Sistema di sicurezza meccanico a balestre unico e imbattibile

- Zero manutenzione

- Protezione e longevità per l’aratro e il trattore

- Aratura di qualità: la sicurezza è individuale su ogni corpo ed è indipendente dagli altri

- Modulazione semplice della tensione di rilascio: svitando due pomelli si possono aggiungere/rimuovere le balestre.

Tipo di balestre |

Tensione di rilascio kN |

Standard 6 balestre |

11,7 |

Standard 6+1 balestre |

13,0 |

HD 7 balestre |

12,7 |

HD 7+1 balestre |

14,2 |

Extra HD 8 balestre |

15,3 |

Extra HD 8+1 balestre |

16,9 |

Regolazione intelligente degli avanvomeri

- Sistema unico centralizzato

- Rapido settaggio contemporaneo dell’avanvomere di destra e sinistra

- Prestazioni d’alto livello: la regolazione degli avanvomeri è fondamentale per un’aratura di qualità

- Disponibilità del coltro a disco: profilo piatto o ondulato (da 45 o 50 cm)

L’importanza del trattamento termico

- Il telaio è una parte fondamentale nella fabbricazione di un aratro e per gli standard Kverneland una parte non trattata termicamente equivale a un punto debole!

- I telai Kverneland sono trattati due volte termicamente per induzione. Il trasferimento termico all’acciaio è attentamente monitorato. Il materiale diventa 3 volte più resistente. L’ineguagliabile trattamento Kverneland conferisce robustezza e flessibilità assicurando una durata estesa.

Più resistente, ma non più pesante

- Per ottenere la stessa robustezza senza trattamento, bisognerebbe aggiungere materiale aumentando spessori e dimensioni, producendo di conseguenza un telaio più pesante.

- Un peso maggiore ha un impatto negativo sulla richiesta di potenza, l’usura, la richiesta di sollevamento, sul trattore e il suo consumo.

Durata estesa

- Le saldature sono altrettanto critiche nel creare punti deboli nell’assemblaggio. I telai Kverneland son in monoblocco, senza saldature!

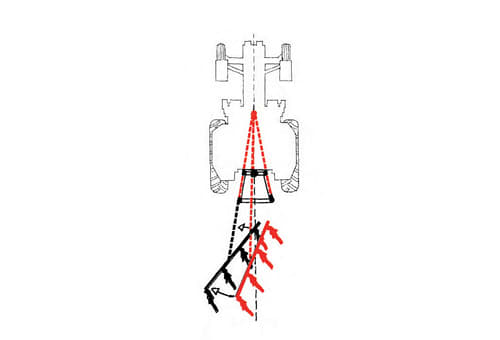

Sistema di regolazione senza fine della larghezza di lavoro Vari-width®, da 30 a 50 cm, in base ai modelli. Questo sistema brevettato da Kverneland è disponibile con regolazione del corpo sia meccanica che idraulica.

I vantaggi:

- Facile variazione della capacità dell’aratro

- Una combinazione perfetta in ogni momento fra capacità del trattore, aratro e condizioni del suolo

- Risparmio di tempo: fino al 30% in più della capacità.

- Risparmio costi di gestione: riduzione fino al 18% in meno del consumo di carburante.

- Un lavoro più efficiente: aratura ai bordi campo, attorno a siepi, alberi e recinzioni.

- Usura minima: Nel sistema Kverneland Vari-width - Variomat® i corpi vengono fissati al telaio per mezzo di due staffe in acciaio sagomate, fissate allo stesso tramite un bullone speciale alla cui estremità vi sono due boccole coniche autocentranti trattate termicamente.

- Una perfetta linea di traino, in qualsiasi momento. Il sistema Kverneland Vari-width offre un allineamento perfetto dell’aratro con l’attacco al trattore. Questa caratteristica riduce la richiesta di potenza e il rischio di usura.

Per un'aratura eccellente

I corpi per aratri Kverneland sono famosi in tutto il mondo grazie a queste caratteristiche:

- Un’aratura di eccellente qualità

- Una straordinaria resistenza all’usura

- Bassa richiesta di potenza

Un acciaio unico al mondo

Tecnologia Kverneland: 12 ore di trattamento termico sull’acciaio che offre:

- Un’ottima resistenza all’usura

- Tutta la flessibilità necessaria per assorbire gli urti

Corpo n. 8 - "Corpo universale"

Per terreni di leggero o medio impasto Buon interramento dei residui

Buone capacità di avanzamento

Profondità: da 15 a 30 cm (da 6 a 12”)

Larghezza: da 30 a 55 cm (da 12 a 22”)

Corpo n. 9 - "Corpo universale di profondità"

Adatto al lavoro nei terreni più difficili

Ottimo avanzamento

Profondità: da 15 a 35 cm (da 6 a 14”)

Larghezza: da 30 a 55 cm (da 12 a 22”)

Corpo n. 28

Adatto ad ogni tipo di suolo, anche a quelli più difficili rispetto al corpo 8

Particolarmente adatto per trattrici dotate di grandi pneumatici

Ottime capacità di avanzamento

Profondità: da 15 a 30 cm (da 6 a 12”)

Larghezza: da 30 a 55 cm (da 12 a 22”)

Corpo n. 30 - "Corpo a dita"

Adatto a terreni tenaci e particolarmente umidi

Ottime capacità di sminuzzamento

Profondità: da 20 a 35 cm (da 8 a 14”)

Larghezza: da 30 a 55 cm (da 12 a 22”)

Corpo n. 34 - Plastica

Forma lunga e sottile (simile al corpo 28)

Per terreni ad alto contenuto di humus senza pietre

Consigliato per trattori con pneumatici di grandi dimensioni

Facile da tirare

Profondità di lavoro: 12-35 cm

Larghezza di lavoro: 30-55 cm

Versoio 40 gradi

Corpo n. 38

Corpo universale - facile da tirare

Per qualsiasi condizione del suolo

Consigliato per trattori con pneumatici di grandi dimensioni dall'aratura profonda a quella poco profonda

Profondità di lavoro: 12-35 cm

larghezza di lavoro: 30-55 cm

Versoio 40 gradi

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Caratteristiche Tecniche

Caratteristiche Tecniche

Scarica il depliant| Modello | 2501S i-Plough® Variomat | 2501S i-Plough® Variomat | |

|---|---|---|---|

| Distanza fra i corpi (cm) | 85 | 100 | |

| Testata | Nº 250 | Nº 250 | |

| Tipo di proiezione | Autom. | Autom. | |

| Larghezza solco (cm) | 30-60 | 30-60 | |

| Distanza fra i corpi (cm) | 80 | 80 | |

| Numero di corpi | 4-6 | 4-6 | |

| Peso (kg), 3 corpi | - | - | |

| Peso (kg), 4 corpi | 1950 | 2010 | |

| Peso (kg), 5 corpi | 2280 | 2355 | |

| Peso (kg), 6 corpi | 2650 | 2810 | |

| Richiesta di sollevamento (kg), 3 corpi | - | - | |

| Richiesta di sollevamento (kg), 4 corpi | 5100 | 5350 | |

| Richiesta di sollevamento (kg), 5 corpi | 6800 | 7050 | |

| Richiesta di sollevamento (kg), 6 corpi | 8800 | 9200 |

Caratteristiche Tecniche

Caratteristiche Tecniche

Scarica il depliantModelli |

Distanza tra i corpi cm |

Testata |

Sicurezza |

Larghezza di lavoro cm |

Luce libera da terra |

No corpi |

2500 B i-Plough Variomat |

85/100 |

250 |

Bullone |

30 - 60 |

80 |

4 - 6 |

2500 S i-Plough Variomat |

85/100 |

250 |

Auto-reset |

30 - 60 |

80 |

4 - 6 |