S series

Erpici rotanti Kverneland garanzia di forza e affidabilità - erpici rotanti su cui potete contare!

La serie Kverneland S è un erpice rotante heay duty per trattori fino a 250 CV.

Punti di forza

Forte resistenza all'abrasione e alla torsione Sbriciolamento completo su tutta la larghezza di lavoro Massima versatilità con tutti i tipi di seminatrici Riduzione del carico di punta e del consumo di carburante Ampia scelta di rulli posterioriDescrizione

Un erpice rotante heavy duty per tutti i tipi di operazioni in tutte le condizioni del terreno. Progettato in modo robusto per l'uso su trattori fino a 250 CV, con il design dellla cassa heavy-duty di Kverneland e i denti Quick-Fit, la serie S è la soluzione giusta per le grandi aziende agricole e i contoterzisti.

La serie S è dotata di serie di denti Quick-Fit. Questi sono fissati da uno speciale perno e clip montati nel portadenti. La sostituzione dei denti è quindi molto semplice senza bisogno di attrezzi. A seconda delle condizioni del terreno, sono disponibili denti attivi per le condizioni più aggressive. Per ottenere prestazioni ottimali in condizioni di terreno difficili, il design della cassa prevede un ampio spazio tra i portadenti e il fondo di essa. Questo permette a grandi quantità di residui e pietre di passare liberamente senza bloccarsi. In solo o in combinazione con seminatrici combinate Kverneland.

Punti di forza

- Forte resistenza all'abrasione e alla torsione della cassa autoportante

- Testata robusta

- Sbriciolamento completo su tutta la larghezza di lavoro grazie a quattro rotori (8 denti) per metro

- Massima versatilità - combinazione facile e semplice con tutti i tipi di seminatrici

- Riduzione del carico e del consumo di carburante

- Ampia scelta di rulli posteriori

Caratteristiche

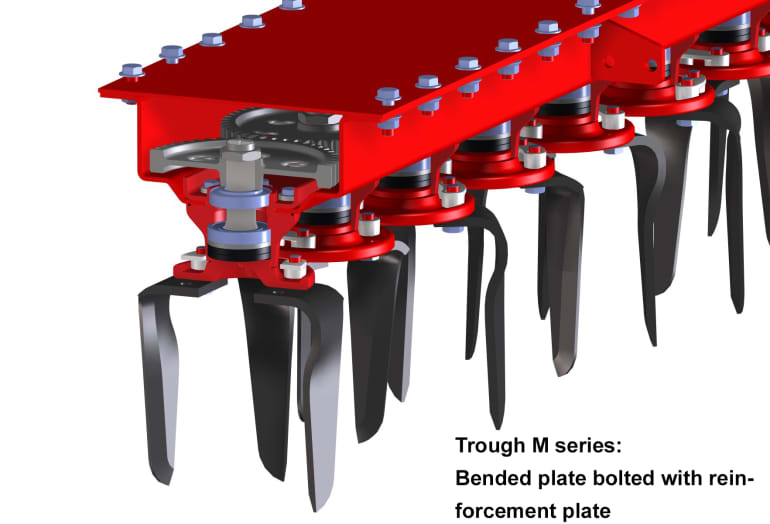

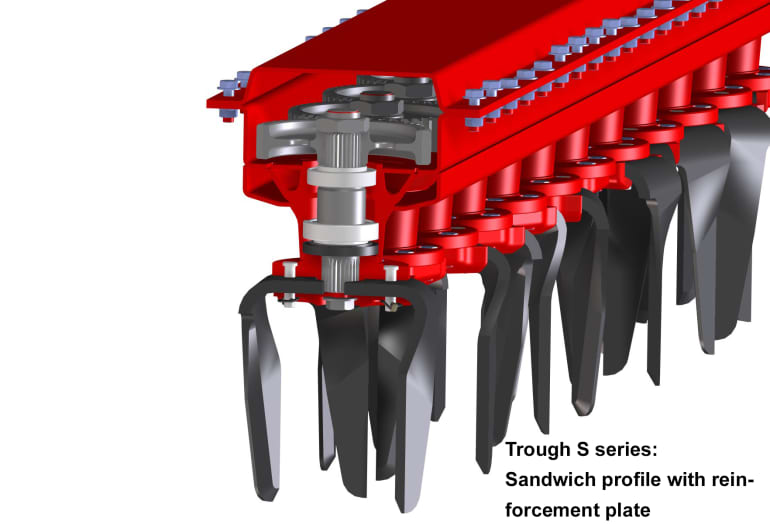

Per prestazioni ottimali in condizioni di terreno difficile, la cassa robusta e auto-portante fornisce un ampio disimpegno tra il porta denti e la sua base. Questo permette un agile passaggio del terreno senza creare blocchi, fornendo un risultato eccellente in presenza di residui colturali e pietre

Modello |

Dimensioni cassa (mm) |

Ingranaggi |

Ø Albero (mm) |

Cuscinetti (mm) |

Distanza tra i cuscinetti (mm) |

Disimpegno del rotore (mm) |

M serie |

140 x 400 |

temperati |

40 & 45 |

80 - 90 |

70 |

98.25 |

H serie |

165 x 400 |

temperati e rinforzati |

45 & 50 |

90 - 100 |

84.5 |

90.5 |

S serie |

200 x 400 |

rinforzati |

55 & 60 |

110 - 120 |

110.5 |

100 |

Tutti i modelli possono essere dotati di dente Standard o Active, così come del supporto denti Quick Fit per venire incontro a tutte le esigenze dei clienti, gli erpici S sono dotati standard di denti Quick-Fit. A seconda delle condizioni del terreno, è possibilescegliere tra denti standard, attivi, denti con rivestimento in carburo e denti in carburo XHD.

Dente Active

Il dente Active assicura un’ottima penetrazione su sodo. Grazie alla sua forma, penetra attivamente nel terreno mantenendo una profondità di lavoro costante e impedendo all’erpice di sollevarsi quando incontra condizioni difficili di terreno duro e secco. In più, aumenta il ri-consolidamento del rullo packer. Il dente Active solleva il terreno e lo spinge in fronte all’erpice rotante permettendo un ottimo livellamento anche delle tracce delle gomme del trattore. Il dente Active può lavorare direttamente su sodo anche in presenza di residui. La sua forma mantiene i residui in superficie; aspetto agronomico necessario per contrastare l’erosione.

Denti XHD

I denti rinforzati in carburo XHD sono protetti in condizioni di terreno estremamente abrasive. Questi denti sono progettati per offrire una maggiore longevità, riducendo al minimo i costi e i tempi di inattività in ambienti in cui i denti standard si usurano troppo rapidamente.

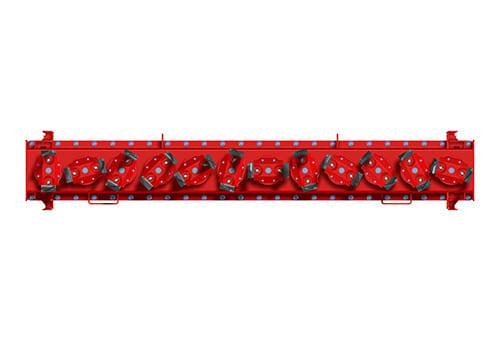

Sistemazione elicoidale dei rotori

L’arrangiamento elicoidale dei 4 rotori per metro riduce i danni da corpi estranei – es. sassi -, migliora il livellamento grazie al flusso di terreno che è diretto verso l’interno e riduce i picchi di carico sulla trasmissione. Sono così garantiti un funzionamento regolare e la riduzione dei consumi. Gli ingranaggi della trasmissione subiscono un trattamento d’indurimento per estenderne la vita utile.

Ri-consolidamento

Come ultimo step della lavorazione, i rulli assicurano il ri-compattamento del letto di semina. Riducendo la porosità e limitando l’evaporazione del suolo, si crea la possibilità per tutte le piante di accedere ai nutrienti, acqua e luce. È la condizione di partenza necessaria per uno sviluppo ottimale ed un’alta produzione.

La gamma di rulli per tutti i tipi di terreno e condizioni:

Actipack ø 560 mm – 205 kg/m

- Si adatta a suoli da medi a pesanti, anche umidi e condizioni pietrose o terreni collosi grazie a slitte e coltelli

- Le creste dei dischi frantumano le zolle e i coltelli regolabili (posizionati tra un disco e l’altro) completano l’affinamento lasciando un letto di semina livellato e ri-consolidato.

Cracker Packer ø 550 mm – 200 kg/m

- Per suoli da medi a pesanti

- Ri-consolidamento a bande (12,5 cm) – solo il 50% della superficie è rullata

- Conferisce una buona penetrazione dell’acqua nel terreno

- Il terreno non ri-consolidato può essere usato per la copertura del seme

- Buon affinamento, specialmente in suoli pesanti

- Creste dei rulli meno aggressive e coltelli lavoranti tra gli elementi garantiscono un ottimo effetto anche in presenza di residui

Rullo Actiline ø550mm - 185 kg/m

- Per terreni leggeri, medi e pesanti

- Rullo trapezoidale con larghezza delle creste relativamente stretta di 40 mm

- Consolidamento a strisce e solco a V davanti alla barra di semina CX-II

- Supporta la capacità di ritenzione idrica e lo scambio di ossigeno

- Buona capacità di trasporto con effetto autopulente completo

- Le creste supportano l'azionamento costante del rullo ed evitano lo slittamento in condizioni leggere o difficili e bagnate

- Due diverse distanze degli anelli di 12,5 cm e 15 cm

- Raschietti rivestiti di carburo su richiesta

Rullo Packer ø 575 mm – 160 kg/m

- Per terreni da medi a pesanti

- Garantisce solidità d’appoggio all’erpice

- Buona capacità di auto-pulirsi

- Regolazione dei raschietti sia centralizzata, sia indipendente

- A richiesta, raschietti al carburo

- Rullo più versatile in gamma – molto adatto per semine in combinata

Rullo a gabbia ø 550 mm – 90 kg/m

- Per terreni da leggeri a medi, lavorati in condizioni asciutte

- Gabbia con 10 barre per migliorare il ri-consolidamento e l’uso in condizioni di terreno umido

La flessibilità è la chiave!

La barra di semina può essere facilmente accoppiata/disaccoppiata con un sistema simile a quello dei caricatori frontali dei trattori. Dato che i tracciatori sono collocati sull’erpice, si può essere operativi in solo in poco tempo. La barra di semina, tramite l’Euro-Connection, è portata sul telaio del rullo. L’aggancio elettro-idraulico è semplice grazie all’interfaccia delle connessioni centralizzata.

La seminatrice e-drill è stata progettata esclusivamente per la combinazione con gli erpici rotanti Kverneland.

Caratteristiche Tecniche

Caratteristiche Tecniche

Scarica il depliant| Modelli | S serie | |

|---|---|---|

| Tipo di macchina | rigido | |

| Larghezza di lavoro (m) | 3.0 | |

| Larghezza di trasporto (m) | 3.0 | |

| Dimensioni cassa (mm) | 200 x 400 | |

| Velocità PTO (rpm) | 1 | |

| Protezione sovraccarico PTO (Nm) | 2,5 | |

| Nr. rotori | 12 | |

| Standard velocità rotore 1000 (rpm) | 298 | |

| Opzione velocità rotore 1000 (rpm) | 365 e 435 | |

| Distanza tra i cuscinetti (mm) | 110.5 | |

| Luce rotori (mm) | 100 | |

| Nr. denti | 24 | |

| Dimensione Denti (mm) | 18 x 330 | |

| Denti Quick-Fit | Standard | |

| Denti Attivi | Opzione | |

| Attacco 3pt alto | CAT 2/CAT 3 | |

| Attacco 3pt basso | CAT 2/CAT 3N/CAT 3 | |

| Reg. profondità | manuale | |

| Barra liv. post. | Opzione | |

| Rompitraccia | Opzione | |

| Rulli | Rullo gabbia (ø 550 mm), Rullo Packer (ø 575 mm), Actiline rullo (ø 550 mm), Cracker Packer rullo (ø 550 mm), Actipack rullo (ø 560 mm) | |

| Pronto per seminatrice portata o integr | Opzione | |

| Luci | Opzione | |

| Peso tot (kg)* | 1,9 | |

| Min. potenza rich. (kW/HP) | 74/100 | |

| Max. potenza rich. (kW/HP) | 184/250 |

* Peso approssimativo con barra liv., rullo packer ø 575 mm e PTO circa.

Caratteristiche Tecniche

Caratteristiche Tecniche

Scarica il depliantModelli |

Larghezza di lavoro (m) |

N. rotori/denti |

Peso con rullo packer(kg) |

Min./max. HP |

S serie |

3.0 |

12/24 |

1,670 |

100/250 |

S serie |

3.5 |

14/28 |

1,950 |

100/250 |

S serie |

4.0 |

16/32 |

2,225 |

100/250 |

S serie |

4.5 |

18/36 |

2,510 |

100/250 |

* Peso approssimativo con barra liv., rullo packer ø 575 mm e PTO circa.